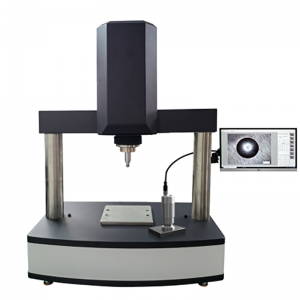

HBST-3000 Moroalo oa motlakase Pontšo ea dijithale Brinell Hardness Tester e nang le Sistimi ea ho Lekanya le PC

* Skrine sa ho ama sa boleng ba Hardness

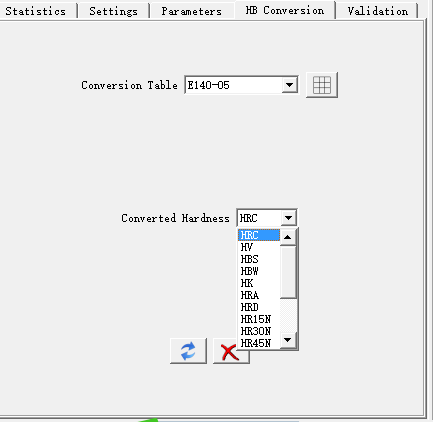

* Phetoho ea thatafalo lipakeng tsa sekala se fapaneng sa thatafalo

* Turret e iketsang, Sesebelisoa se amohela ts'ebeliso ea matla a teko a enjene ntle le li-block tsa boima

* Ts'ebetso ea teko e iketsang, ha ho na phoso ea ts'ebetso ea motho ;

* Skrine ea ho ama ea ts'ebetso ea liteko, ts'ebetso e bonolo ;

* Ho nepahala ho latela GB/T 231.2, ISO 6506-2 le ASTM E10

Sebaka sa ho lekanya: 8-650HBW

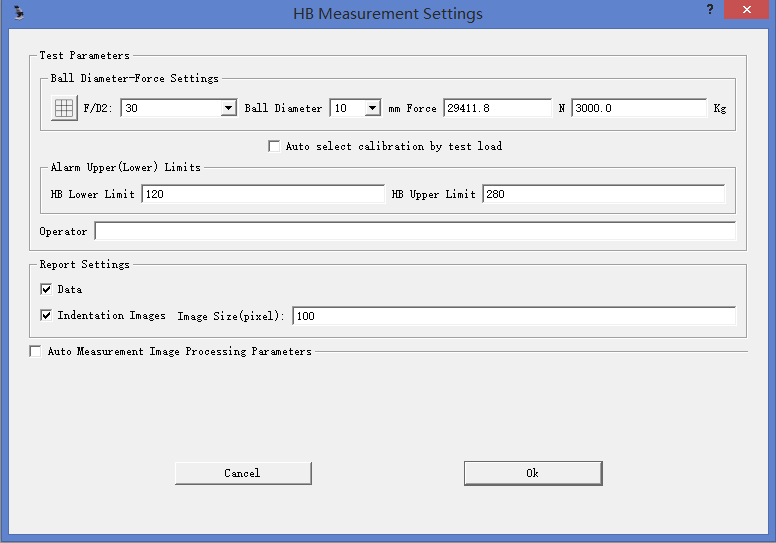

Matla a teko: 612.9,980.7,1226,1839, 2452, 4903,7355, 9807, 14710, 29420N (62.5, 100, 125, 187.5, 250, 500, 750, 1000, 1500, 3000kgf)

Bolelele bo phahameng ba karolo ea teko: 280mm

Botebo ba 'metso: 170mm

Ho Bala ka Bothata: Pontšo ea dijithale ea LCD

Boleng bo tlase ba lebili la moropa: 1.25μm

Bophara ba bolo ea tungsten carbide: 2.5, 5, 10mm

Nako ea bolulo ea matla a teko: 0 ~ 60S

Tlhahiso ea data: Printa e hahiloeng kahare, RS232/ e ka hokela khomphutha ho printa

Ho sebetsana le mantsoe: Excel kapa leqephe la Word

Phepelo ea motlakase: AC 110V/ 220V 60/50HZ

Litekanyo:581*269*912mm

Boima ba 'mele: Hoo e ka bang 135kg

| Yuniti e ka sehloohong 1 | Brinell e tloaelehileng boloko 2 |

| Φ110mm Sekoahelo se seholo se bataletseng 1 | Thapo ea motlakase 1 |

| Φ60mm Sekoahelo se senyenyane se bataletseng 1 | Spanner 1 |

| Anvil ea Φ60mm V-notch 1 | Setifikeiti sa 1 |

| Sepetlele sa Tungsten carbide: Φ2.5, Φ5, Φ10mm, pc e le 'ngoe ka' ngoe | Buka ea mosebelisi: 1 |

| Sekoahelo se thibelang lerōle 1 | Khomphutha, adaptara ea CCD le Software 1 |

Sistimi ea Tekanyo ea Brinell Hardness Indentation Automatic

(E ka kenngoa ho teko ea ho thatafala kapa ea sebetsa e le khomphutha e arohaneng)

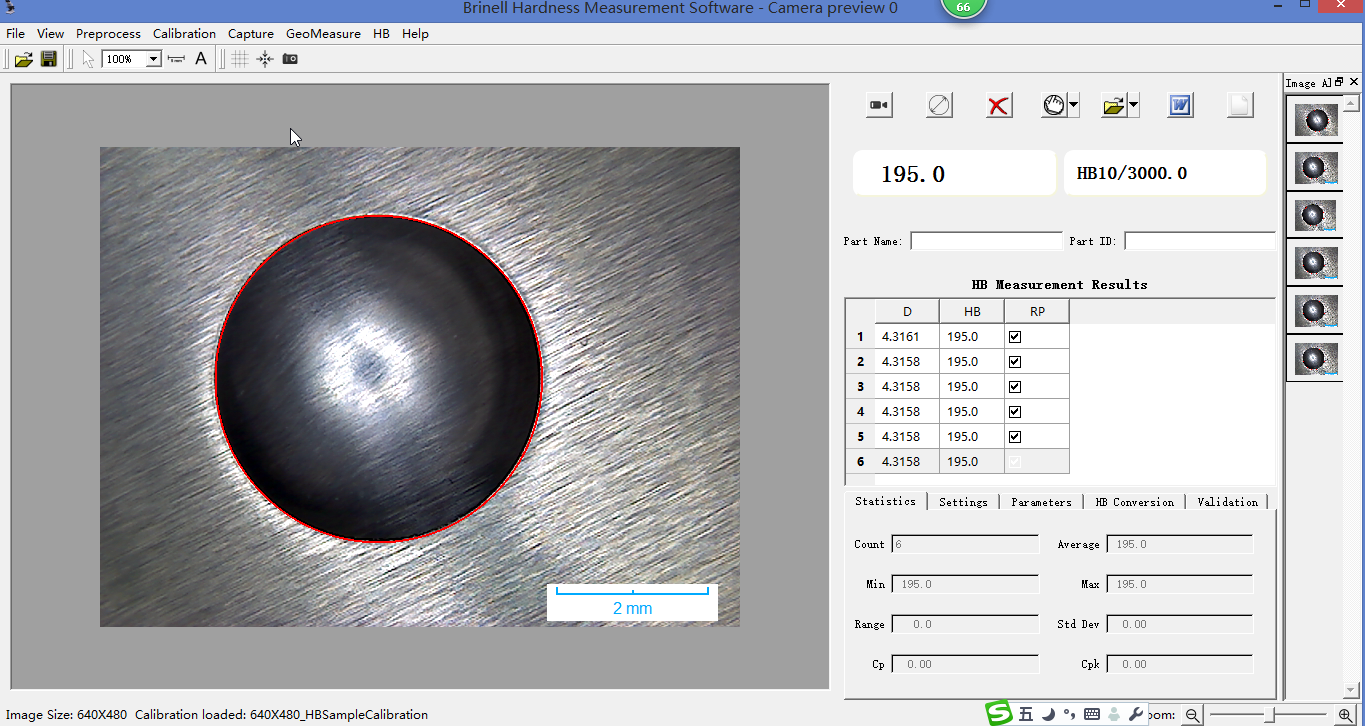

1. Tekanyo e iketsang: Tšoara ho teba ha lesoba ka bohona ebe o lekanya bophara ebe o bala boleng bo tsamaellanang ba thatafalo ea Brinell;

2. Tekanyo ea letsoho: Lekanya ho kenella ha lesoba ka letsoho, sistimi e bala boleng bo tsamaellanang ba thatafalo ea Brinell;

3. Phetoho ea thatafalo: Sistimi e ka fetola boleng ba thatafalo ba Brinell bo lekantsoeng HB ho boleng bo bong ba thatafalo joalo ka HV, HR jj;

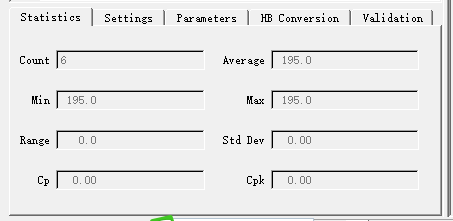

4. Lipalopalo tsa data: Sistimi e ka bala ka bohona boleng bo tloaelehileng, phapang le boleng bo bong ba lipalo-palo ba bothata;

5. Alamo e tloaelehileng e fetang: Tšoaea boleng bo sa tloaelehang ka bohona, ha boima bo feta boleng bo boletsoeng, bo alamo ka bohona;

6. Tlaleho ea teko: Hlahisa tlaleho ea sebopeho sa WORD ka bo eona, litempele tsa tlaleho li ka fetoloa ke mosebelisi.

7. Polokelo ea data: Lintlha tsa tekanyo ho kenyeletsoa le setšoantšo sa ho kenella li ka bolokoa faeleng.

8. Mesebetsi e meng: e kenyelletsa mesebetsi yohle ya tsamaiso ya ho sebetsana le ditshwantsho le ho lekanya, jwalo ka ho hapa ditshwantsho, ho lekanya, ho sebetsana le ditshwantsho, ho lekanya jiometri, tlhaloso, tsamaiso ya dialebamo tsa difoto le dinako tse tsitsitseng tsa ho hatisa jj.

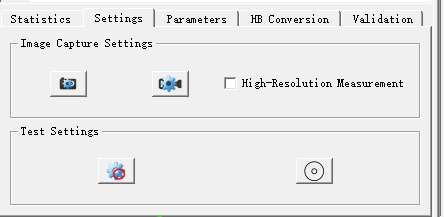

1. Ho bonolo ho e sebelisa: Tobetsa konopo ea sebopeho kapa tobetsa konopo ea khamera kapa tobetsa konopo ea ho matha ho phethela mosebetsi oohle ka bohona; haeba ho hlokahala tekanyo ea letsoho kapa ho fetola liphetho, hula mouse feela;

2.Khanyetso e matla ea lerata: Theknoloji e tsoetseng pele le e tšepahalang ea ho lemoha setšoantšo e ka sebetsana le ho lemoha ho kenella ha sekoti holim'a sampole e rarahaneng, mefuta e 'meli ea mokhoa oa ho lekanya o iketsang ho sebetsana le boemo bo feteletseng;