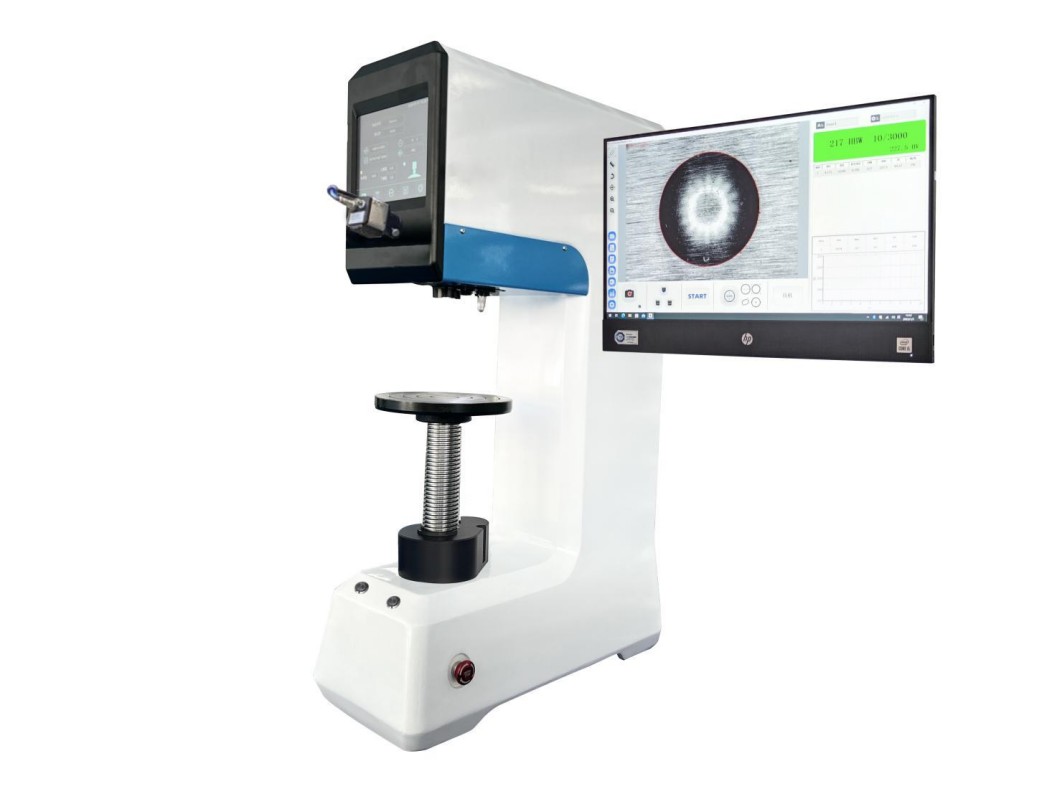

Teko ea ho thatafala ha Brinell e qapiloe ke moenjiniere oa Sweden Johan August Brinell ka 1900 'me e ile ea sebelisoa ka lekhetlo la pele ho lekanya ho thatafala ha tšepe.

(1)HB10/3000

①Mokhoa le molao-motheo oa teko: Bolo ea tšepe e bophara ba 10 mm e hatelloa holim'a thepa tlas'a mojaro oa 3000 kg, 'me bophara ba ho kenella bo lekanngoa ho bala boleng ba thatafalo.

②Mefuta ea thepa e sebetsang: E loketse lisebelisoa tsa tšepe tse thata joalo ka tšepe e entsoeng ka tšepe, tšepe e thata, metsoako e boima, jj.

③Maemo a tloaelehileng a ts'ebeliso: Teko ea thepa ea mechini le lisebelisoa tse boima. Teko ea ho tiea ha li-castings tse kholo le li-forging. Taolo ea boleng boenjiniere le tlhahiso.

④Litšobotsi le melemo: Mojaro o moholo: E loketse thepa e teteaneng le e thata, e ka mamella khatello e kholo, 'me ea netefatsa liphetho tse nepahetseng tsa tekanyo. Ho tšoarella: Sesebelisoa sa tšepe se tšoarellang se tšoarella haholo 'me se loketse tšebeliso ea nako e telele le e pheta-phetoang. Mefuta e mengata ea lits'ebetso: E khona ho leka mefuta e fapaneng ea lisebelisoa tsa tšepe tse thata.

⑤Lintlha kapa meedi: Boholo ba sampole: Ho hlokahala sampole e kholoanyane ho netefatsa hore ho kenella ho hoholo ka ho lekaneng le ho nepahetseng, 'me bokaholimo ba sampole bo lokela ho ba bataletse ebile bo hloekile. Litlhoko tsa bokaholimo: Bokaholimo bo hloka ho ba bo boreleli ebile bo se na litšila ho netefatsa ho nepahala ha tekanyo. Tlhokomelo ea lisebelisoa: Lisebelisoa li hloka ho lekanngoa le ho hlokomeloa khafetsa ho netefatsa ho nepahala le ho pheta-pheta ha teko.

(2)HB5/750

①Mokhoa le molao-motheo oa teko: Sebelisa bolo ea tšepe e bophara ba 5 mm ho hatella holim'a thepa tlas'a mojaro oa 750 kg, 'me u lekanye bophara ba intentation ho bala boleng ba thatafalo.

②Mefuta ea thepa e sebetsang: E sebetsa ho thepa ea tšepe e nang le bothata bo mahareng, joalo ka li-alloy tsa koporo, li-alloy tsa aluminium, le tšepe ea bothata bo mahareng. ③ Maemo a tloaelehileng a ts'ebeliso: Taolo ea boleng ba thepa ea tšepe ea bothata bo mahareng. Patlisiso ea thepa le nts'etsopele le liteko tsa laboratori. Teko ea bothata ba thepa nakong ea tlhahiso le ts'ebetso. ④ Likarolo le melemo: Mojaro o mahareng: E sebetsa ho thepa e nang le bothata bo mahareng 'me e ka lekanya bothata ba tsona ka nepo. Tšebeliso e tenyetsehang: E sebetsa ho mefuta e fapaneng ea thepa ea bothata bo mahareng e nang le bokhoni bo matla ba ho ikamahanya le maemo. Ho pheta-pheta ho hoholo: E fana ka liphetho tse tsitsitseng le tse tsitsitseng tsa tekanyo.

⑥Lintlha kapa meedi: Tokiso ea sampole: Bokaholimo ba sampole bo hloka ho ba bataletse le ho hloeka ho netefatsa ho nepahala ha liphetho tsa tekanyo. Meedi ea thepa: Bakeng sa thepa e bonolo haholo kapa e thata haholo, mekhoa e meng e loketseng ea teko ea ho thatafala e ka 'na ea hloka ho khethoa. Tlhokomelo ea lisebelisoa: Lisebelisoa li hloka ho lekanngoa le ho hlokomeloa khafetsa ho netefatsa ho nepahala le ho tšepahala ha tekanyo.

(3)HB2.5/187.5

①Mokhoa le molao-motheo oa teko: Sebelisa bolo ea tšepe e bophara ba 2.5 mm ho hatella holim'a thepa tlas'a mojaro oa 187.5 kg, 'me u lekanye bophara ba intentation ho bala boleng ba thatafalo.

②Mefuta ea thepa e sebetsang: E sebetsa ho thepa ea tšepe e bonolo le metsoako e meng e bonolo, joalo ka aluminium, motsoako oa loto le tšepe e bonolo.

③Maemo a tloaelehileng a ts'ebeliso: Taolo ea boleng ba thepa ea tšepe e bonolo. Teko ea thepa indastering ea lisebelisoa tsa elektroniki le tsa motlakase. Teko ea ho thatafala ha thepa e bonolo nakong ea tlhahiso le ts'ebetso.

④Litšobotsi le melemo: Mojaro o tlase: E sebetsa ho thepa e bonolo ho qoba ho kobeha ho feteletseng. Ho pheta-pheta ho hoholo: E fana ka liphetho tse tsitsitseng le tse tsitsitseng tsa tekanyo. Mefuta e mengata ea lits'ebetso: E khona ho leka mefuta e fapaneng ea thepa ea tšepe e bonolo.

⑤ Lintlha kapa meedi: Tokiso ea sampole: Bokaholimo ba sampole bo hloka ho ba bataletseng le ho hloeka ho netefatsa ho nepahala ha liphetho tsa tekanyo. Meedi ea thepa: Bakeng sa thepa e thata haholo, ho ka hlokahala ho khetha mekhoa e meng e loketseng ea teko ea ho thatafala. Tlhokomelo ea lisebelisoa: Lisebelisoa li hloka ho lekanngoa le ho hlokomeloa khafetsa ho netefatsa ho nepahala le ts'epo ea tekanyo.

Nako ea poso: Pulungoana-20-2024