Khoutu ea ho thatafala ha tšepe ke H. Ho ea ka mekhoa e fapaneng ea teko ea ho thatafala, litšoantšo tse tloaelehileng li kenyelletsa Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), ho thatafala ha Shore (HS), jj., tseo har'a tsona HB le HRC li sebelisoang haholo. HB e na le mefuta e mengata ea lits'ebetso, 'me HRC e loketse lisebelisoa tse nang le bothata bo phahameng ba bokaholimo, joalo ka bothata ba kalafo ea mocheso. Phapang ke hore indenter ea teko ea ho thatafala e fapane. Teko ea ho thatafala ha Brinell ke indenter ea bolo, ha teko ea ho thatafala ha Rockwell e le indenter ea daemane.

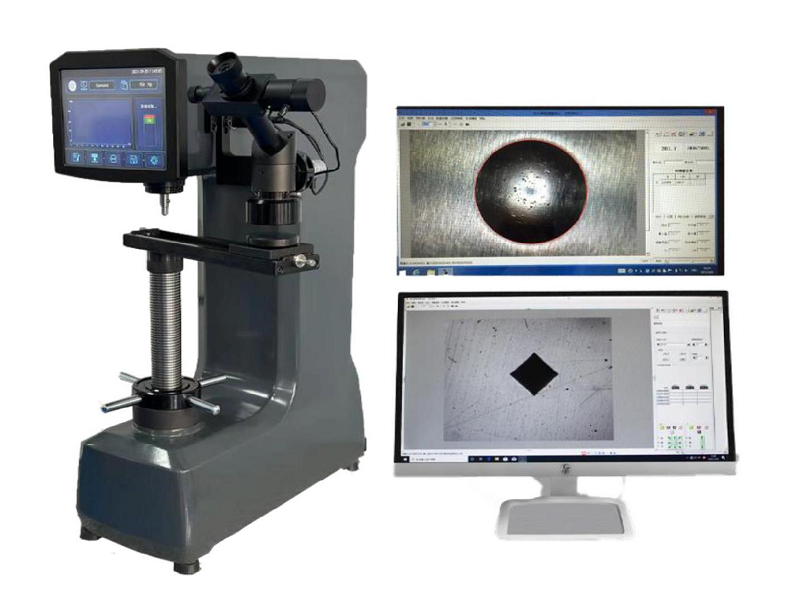

HV-e loketse tlhahlobo ea microscope. Vickers hardness (HV) Tobetsa bokaholimo ba thepa ka mojaro o ka tlase ho 120kg le indenter ea khoune ea daemane e sekwere e nang le sekhutlo sa vertex sa 136°. Sebaka sa bokaholimo ba mokoti oa ho kenella ha thepa se arotsoe ka boleng ba mojaro, e leng boleng ba hardness ba Vickers (HV). Hardness ea Vickers e hlalosoa e le HV (sheba GB/T4340-1999), 'me e lekanya disampole tse tšesaane haholo.

Teko ea ho thatafala e nkehang habobebe ea HL e bonolo ho e lekanya. E sebelisa hlooho ea bolo ea tšusumetso ho ama bokaholimo ba thata le ho hlahisa ho kgutla. Bothata bo baloa ka karolelano ea lebelo la ho kgutla ha punch ho 1mm ho tloha bokaholimong ba sampole ho ea lebelong la tšusumetso. Foromo ke: Bothata ba Leeb HL=1000×VB (lebelo la ho kgutla)/VA (lebelo la tšusumetso).

Teko ea boima ba Leeb e nkehang habobebe e ka fetoloa ho ba boima ba Brinell (HB), Rockwell (HRC), Vickers (HV), Shore (HS) kamora ho lekanya Leeb (HL). Kapa sebelisa molao-motheo oa Leeb ho lekanya ka kotloloho boleng ba boima ka Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL), Shore (HS).

Bothata ba HB - Brinell:

Bothata ba Brinell (HB) hangata bo sebediswa ha thepa e le bonolo, jwalo ka ditshipi tse se nang ferrous, tshepe pele ho kalafo ya mocheso kapa kamora ho annealing. Bothata ba Rockwell (HRC) hangata bo sebediswa bakeng sa thepa e nang le bothata bo hodimo, jwalo ka boima kamora kalafo ya mocheso, jj.

Bohloko ba Brinell (HB) ke mojaro oa teko oa boholo bo itseng. Bolo ea tšepe e thatafetseng kapa bolo ea carbide ea bophara bo itseng e hatelloa holim'a tšepe hore e lekoe. Mojaro oa teko o bolokoa ka nako e itseng, ebe mojaro oa tlosoa ho lekanya bophara ba ho kobeha holim'a metsi ho tla lekoa. Boleng ba bothata ba Brinell ke quotient e fumanoang ka ho arola mojaro ka sebaka sa bokaholimo ba ho kobeha. Ka kakaretso, bolo ea tšepe e thatafetseng ea boholo bo itseng (hangata bophara ba 10mm) e hatelloa holim'a thepa ka mojaro o itseng (hangata 3000kg) 'me e bolokoa ka nako e itseng. Kamora hore mojaro o tlosoe, karolelano ea mojaro le sebaka sa ho kobeha ke boleng ba boima ba Brinell (HB), 'me yuniti ke matla a kilogram/mm2 (N/mm2).

Bothata ba Rockwell bo fumana boleng ba boima bo ipapisitseng le botebo ba ho fetoha ha polasetiki ha ho kobeha. 0.002 mm e sebediswa e le yuniti ya boima. Ha HB>450 kapa sampole e le nyane haholo, teko ya boima ba Brinell e ke ke ya sebediswa mme ho sebediswa tekanyo ya boima ba Rockwell. E sebedisa khoune ya daemane e nang le sekhutlo sa vertex sa 120° kapa bolo ya tshepe e nang le bophara ba 1.59 kapa 3.18mm ho hatella hodima thepa e tlasa teko tlasa mojaro o itseng, mme boima ba thepa bo balwa ho tloha botebong ba ho kobeha. Ho ya ka boima ba thepa ya teko, bo hlahiswa ka dikala tse tharo tse fapaneng:

HRA: Ke boima bo fumanoang ka ho sebelisa mojaro oa 60kg le indenter ea khoune ea daemane, e sebelisetsoang thepa e thata haholo (joalo ka carbide e samentetsoeng, jj.).

HRB: Ke boima bo fumanoang ka ho sebelisa mojaro oa 100kg le bolo ea tšepe e thatafetseng e bophara ba 1.58mm, e sebelisetsoang thepa e nang le boima bo tlase (joalo ka tšepe e annealed, tšepe e entsoeng ka tšepe, jj.).

HRC: Ke boima bo fumanoang ka ho sebelisa mojaro oa 150kg le indenter ea khoune ea daemane, e sebelisetsoang thepa e nang le boima bo phahameng haholo (joalo ka tšepe e thatafalitsoeng, jj.).

Holim'a moo:

1.HRC e bolela boima ba Rockwell C sekala.

2.HRC le HB li sebelisoa haholo tlhahisong.

3.HRC sebaka se sebetsang HRC 20-67, se lekanang le HB225-650,

Haeba bothata bo phahame ho feta tekanyo ena, sebelisa Rockwell hardness A scale HRA,

Haeba bothata bo le tlase ho feta tekanyo ena, sebelisa Rockwell hardness B scale HRB,

Moeli o ka holimo oa bothata ba Brinell ke HB650, e leng se ke keng sa ba holimo ho feta boleng bona.

4. Sekala sa teko sa Rockwell hardness tester C ke khoune ea daemane e nang le sekhutlo sa vertex sa likhato tse 120. Moroalo oa teko ke boleng bo itseng. Tekanyetso ea Sechaena ke 150 kgf. Sekala sa teko sa teko ea Brinell hardness tester ke bolo ea tšepe e thata (HBS) kapa bolo ea carbide (HBW). Moroalo oa teko o fapana ho latela bophara ba bolo, ho tloha ho 3000 ho isa ho 31.25 kgf.

5. Ho teba ha Rockwell ho nyane haholo, mme boleng bo lekantsoeng bo fumaneha sebakeng seo. Ho hlokahala ho lekanya lintlha tse 'maloa ho fumana boleng bo tloaelehileng. E loketse lihlahisoa tse felileng le likotoana tse tšesaane 'me e arotsoe e le teko e sa senyeheng. Ho teba ha Brinell ho hoholo, boleng bo lekantsoeng bo nepahetse, ha boa lokela lihlahisoa tse felileng le likotoana tse tšesaane, 'me ka kakaretso ha bo khetholloe e le teko e sa senyeheng.

6. Boleng ba ho thatafala ha Rockwell ke palo e sa bolelwang ka lebitso ntle le diyuniti. (Ka hona, ha ho a nepahala ho bitsa ho thatafala ha Rockwell ka tekanyo e itseng.) Boleng ba ho thatafala ha Brinell bo na le diyuniti mme bo na le kamano e itseng e hakanyetsoang le matla a ho thaepa.

7. Bothata ba Rockwell bo bontšoa ka ho toba daeleng kapa bo bontšoa ka dijithale. Ho bonolo ho bo sebelisa, bo potlakile ebile bo utloahala habonolo, 'me bo loketse tlhahiso ea bongata. Bothata ba Brinell bo hloka microscope ho lekanya bophara ba indentation, ebe o sheba tafoleng kapa o bala, e leng ntho e boima ho e sebelisa.

8. Tlas'a maemo a itseng, HB le HRC li ka fapanyetsanoa ka ho sheba tafoleng. Foromo ea lipalo ea kelello e ka tlalehoa ka mokhoa o batlang o tšoana le: 1HRC≈1/10HB.

Teko ea ho thatafala ke mokhoa o bonolo le o bonolo oa teko tekong ea thepa ea mechini. E le ho sebelisa teko ea ho thatafala ho nkela liteko tse itseng tsa thepa ea mechini sebaka, kamano e nepahetseng haholoanyane ea phetoho pakeng tsa ho thatafala le matla ea hlokahala tlhahisong.

Mokhoa o pakile hore ho na le kamano e batlang e tsamaellana pakeng tsa boleng bo fapaneng ba ho thatafala ha thepa ea tšepe le pakeng tsa boleng ba ho thatafala le boleng ba matla. Hobane boleng ba ho thatafala bo khethoa ke khanyetso ea pele ea ho feto-fetoha ha polasetiki le khanyetso e tsoelang pele ea ho feto-fetoha ha polasetiki, ha matla a thepa a ntse a phahama, khanyetso ea ho feto-fetoha ha polasetiki e ntse e phahama, 'me boleng ba ho thatafala bo ntse bo phahama.

Nako ea poso: Phato-16-2024