1 Litokisetso pele ho tlhahlobo

1) Sesebelisoa sa ho lekola bothata le sa ho lekanya boima se sebediswang bakeng sa teko ya thata ya Vickers se lokela ho latela dipehelo tsa GB/T4340.2;

2) Mocheso oa kamore ka kakaretso o lokela ho laoloa ka har'a sebaka sa 10 ~ 35℃. Bakeng sa liteko tse nang le litlhoko tse phahameng tsa ho nepahala, o lokela ho laoloa ho (23±5)℃.

Mehlala e 2

1) Bokaholimo ba sampole bo lokela ho ba bataletse ebile bo boreleli. Ho kgothaletswa hore ho ba thata ha sampole bo fihlelle ditlhoko: Boleng bo hodimo ba paramethara ya ho ba thata ha bokaholimo: Sampole ya ho ba thata ha Vickers 0.4 (Ra)/μm; sampole ya ho ba thata ha Vickers e nyane 0.2 (Ra)/μm; sampole ya ho ba thata ha Vickers e nyane 0.1 (Ra)/μm

2) Bakeng sa disampole tsa Vickers tse nyane le tsa micro Vickers, ho kgothaletswa ho kgetha ho bentsha le ho bentsha ka electrolytic bakeng sa kalafo ya bokahodimo ho latela mofuta wa thepa.

3) Botenya ba sampole kapa lera la teko e lokela ho ba bonyane ka makhetlo a 1.5 ho feta bolelele ba diagonal ba indentation

4) Ha o sebedisa mojaro o monyane le di-Vicker tse nyane bakeng sa teko, haeba sampole e le nyane haholo kapa e sa tlwaeleha, sampole e lokela ho manehwa kapa ho tlangwa ka sesebediswa se ikgethang pele o etsa teko.

3Mokhoa oa teko

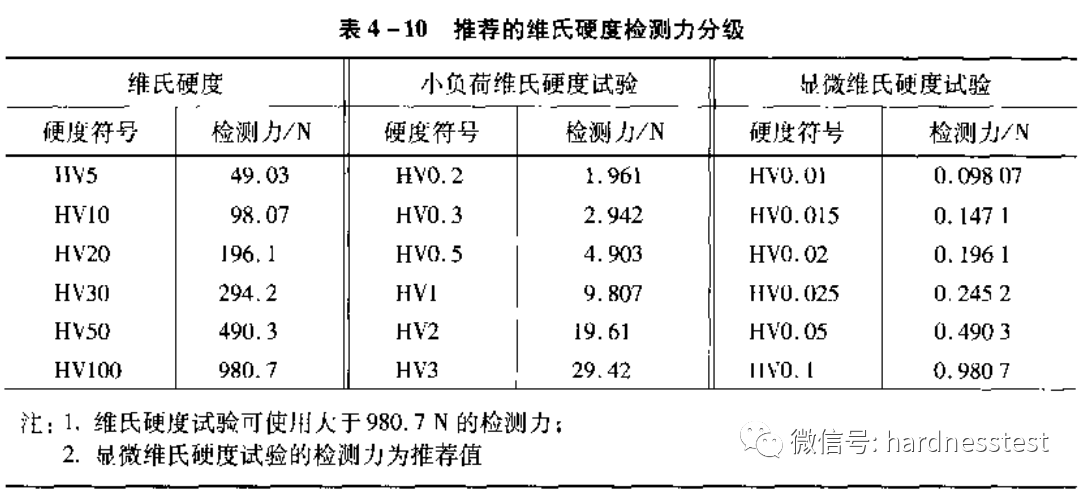

1) Khetho ea matla a teko: Ho ea ka boima, botenya, boholo, jj. ba sampole, matla a teko a bontšitsoeng ho Tafole ea 4-10 a lokela ho khethoa bakeng sa teko.

2) Nako ea ho sebelisa matla a teko: Nako ho tloha qalong ea ho sebelisa matla ho fihlela qetellong ea ho sebelisa matla a teko ka botlalo e lokela ho ba ka har'a metsotsoana e 2 ~ 10. Bakeng sa liteko tse nyane tsa Vickers le tsa micro Vickers tsa boima, lebelo la ho theoha ha indenter ha lea lokela ho feta 0.2 mm/s. Nako ea ho tšoara matla a teko ke metsotsoana e 10 ~ 15. Bakeng sa thepa e bonolo haholo, nako ea ho tšoara e ka atolosoa, empa phoso e lokela ho ba ka har'a metsotsoana e 2.

3) Sebaka ho tloha bohareng ba ho kenella ho ea moeling oa sampole: Tšepe, koporo le li-alloy tsa koporo li lokela ho ba bonyane ka makhetlo a 2.5 bolelele ba diagonal ba ho kenella; litšepe tse bobebe, loto, tin le li-alloy tsa tsona li lokela ho ba bonyane ka makhetlo a 3 bolelele ba diagonal ba ho kenella. Sebaka se pakeng tsa litsi tsa li-alloy tse peli tse haufi: bakeng sa li-alloy tsa tšepe, koporo le koporo, e lokela ho ba bonyane ka makhetlo a 3 bolelele ba mola o otlolohileng oa letšoao la ho emisa; bakeng sa litšepe tse bobebe, loto, tin le li-alloy tsa tsona, e lokela ho ba bonyane ka makhetlo a 6 bolelele ba mola o otlolohileng oa ho kenella.

4) Lekanya karolelano ea lipalo tsa bolelele ba li-diagonal tse peli tsa indentation, 'me u fumane boleng ba thata ba Vickers ho latela tafole, kapa u bale boleng ba thata ho latela foromo.

Phapang boleleleng ba didaegonale tse pedi tsa ho kenella ha dibopeho tse ka hare ho sefofane ha ea lokela ho feta 5% ya boleng bo tloaelehileng ba didaegonale. Haeba e feta, e lokela ho hlokomelwa tlalehong ya teko.

5) Ha ho etsoa liteko holim'a sampole ea bokaholimo bo kobehileng, liphetho li lokela ho lokisoa ho latela tafole.

6) Ka kakaretso, ho kgothaletswa ho tlaleha boleng ba teko ya thatafalo ya dintlha tse tharo bakeng sa sampole ka nngwe.

Sehlopha sa liteko tsa ho thatafala ha Vickers

Ho na le mefuta e 'meli ea liteko tsa thata tsa Vickers tse sebelisoang haholo. Se latelang ke selelekela sa tšebeliso ea liteko tsa thata tsa Vickers tse sebelisoang haholo:

1. Mofuta oa tekanyo ea leihlo;

2. Mofuta oa tekanyo ea software

Sehlopha sa 1: Mofuta wa tekanyo ya leihlo Dikarolo: Sebedisa leihlo ho lekanya. Tshebediso: Mochini o etsa lesoba (daemane ◆), mme bolelele ba taemane bo lekanngwa ka leihlo ho fumana boleng ba thatafalo.

Sehlopha sa 2: Mofuta oa tekanyo ea software: Likarolo: Sebelisa software ea ho thatafala ho lekanya; e bonolo ebile e bonolo mahlong; e ka lekanya ho thatafala, bolelele, ea boloka litšoantšo tsa ho kobeha, litlaleho tsa litaba, jj. Tšebeliso: Mochini o etsa ho kobeha ha (daemane ◆), 'me khamera ea dijithale e bokella ho kobeha ha khomphutha, 'me boleng ba ho thatafala bo lekanngoa khomphutheng.

5Tlhophiso ea software: Mefuta e 4 ea motheo, mofuta oa taolo ea turret o iketsang, mofuta oa halofo ea othomathiki, le mofuta oa othomathiki o felletseng.

1. Phetolelo ea motheo

E ka lekanya boima, bolelele, ea boloka litšoantšo tsa ho kenella, litlaleho tsa litaba, jj.;

2.Laola software ea mofuta oa turret e iketsang e ka laola turret ea teko ea ho thatafala, joalo ka, lense ea sepheo, indenter, ho kenya, jj.;

3. Mofuta o itekanetseng ka ho feletseng o nang le tafole ea teko ea XY ea motlakase, lebokose la taolo la sethala sa 2D; Ntle le ts'ebetso ea mofuta oa turret o ikemetseng, software e ka boela ea beha sebaka le lintlha, ho etsa matheba ka bo eona, ho lekanya ka bo eona, jj.;

4. Mofuta o iketsang ka botlalo o nang le tafole ea teko ea XY ea motlakase, lebokose la taolo ea sethala sa 3D, tlhokomelo ea axis ea Z; Ntle le ts'ebetso ea mofuta o iketsang ka halofo, software e boetse e na le ts'ebetso ea tlhokomelo ea axis ea Z;

6Mokhoa oa ho khetha sesebelisoa se loketseng sa ho lekola bothata ba Vickers

Theko ea teko ea ho thatafala ha Vickers e tla fapana ho latela sebopeho le ts'ebetso.

1. Haeba o batla ho kgetha e theko e tlase ka ho fetisisa, o ka kgetha:

Lisebelisoa tse nang le skrine e nyane ea LCD le ho kenngoa ka letsoho ka tsela e otlolohileng ka har'a eyepiece;

2. Haeba o batla ho kgetha sesebediswa se theko e tlase, o ka kgetha:

Lisebelisoa tse nang le skrine e kholo ea LCD, sesebelisoa sa mahlo se nang le encoder ea dijithale, le printa e hahiloeng kahare;

3. Haeba o batla sesebediswa se maemo a hodimo, o ka kgetha:

Lisebelisoa tse nang le sekirini se amang, sensor e koetsoeng, eyepiece e nang le printa (kapa USB flash drive), screw ea ho phahamisa gear ea worm, le encoder ea dijithale;

4. Haeba o nahana hore hoa tena ho lekanya ka eyepiece, o ka kgetha:

E na le sistimi ea ho sebetsana le litšoantšo tsa CCD, lekanya khomphuteng ntle le ho sheba eyepiece, e leng bonolo, e utloahalang, le e potlakileng. U ka boela ua hlahisa litlaleho le ho boloka litšoantšo tsa ho kenella, jj.

5. Haeba o batla ts'ebetso e bonolo le othomathike e phahameng, o ka khetha:

Teko ea boima ba Vickers e iketsang le teko ea boima ba Vickers e iketsang ka botlalo

Likarolo: beha sebaka le palo ea lintlha, ka boiketsetso le ka ho tsoelang pele, 'me u lekanye ka boiketsetso.

Nako ea poso: Mphalane-17-2024